COMPLETE SOLUTIONS

TURNKEY FOR BIOMETHANE PRODUCTION:

German technology made in Brazil

because the future is green

SOLUTIONS FOR YOUR BIOMETHANE PROJECT

ABOUT GRUEN BIOGÁS

Established in Brazil in 2020, with headquarters in São Paulo, Gruen Biogás houses an engineering team that operates both in Brazil and in Germany, thereby ensuring the development of the most efficient process for each project. Our mission is to provide the perfect technology for biogas purification with the lowest energy consumption compared to all other processes available in the market.

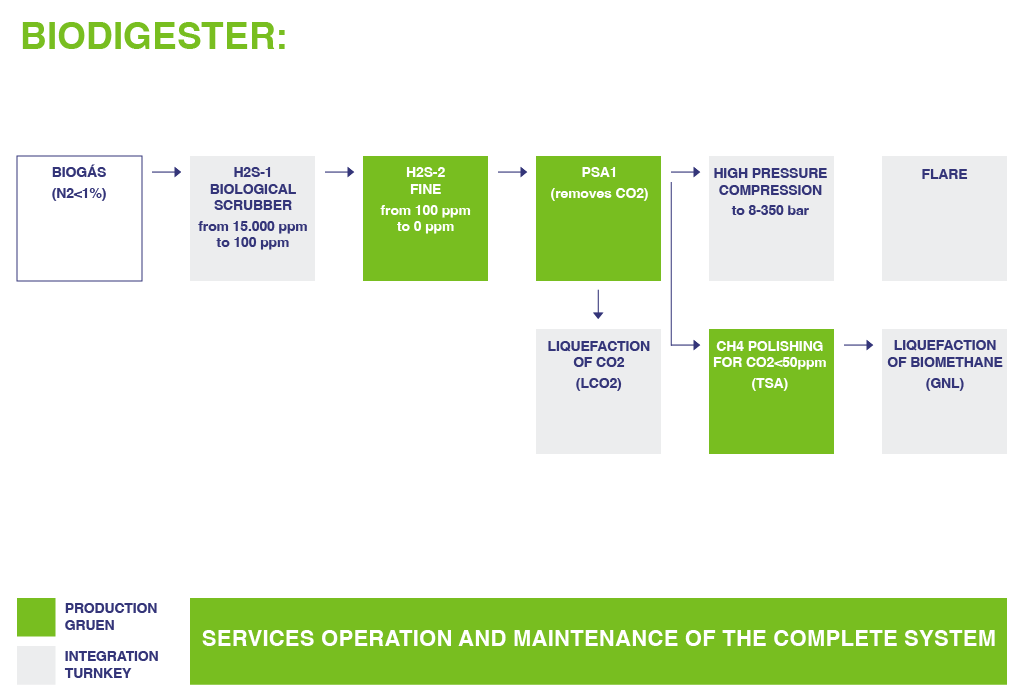

Our solutions are tailored and customized to meet the specific requirements of our customers: gas pre-treatment, removal of CO2 and N2, optional CO2 capture and storage or liquefaction, CH4 liquefaction or high-pressure compression – from project inception to plant operation management, we guarantee complete customer satisfaction throughout the entire process.

Local manufacturing and service operations leads to significant cost savings and enhanced operational efficiency with local service experts in Brazil.

Solutions for plant maintenance and operation contracts make it possible to reduce the complexity and costs involved for our customers.

Gruen’s goal is to develop viable solutions for the generation of clean and sustainable energy to preserve our planet now and for generations to come.

Our aim is to design and deliver solutions that provide optimal technical design and maximum economic return for the customer in every biomethane project undertaken in Brazil.

Alexander Röpke

CEO Gruen

With the know-how of the PSA process acquired in Germany, he founded Gruen Biogás in 2020, with the main objective of bringing the concept of the advanced PSA cycle with local manufacturing to Brazil, thus enabling a greater volume of investments in the generation of biomethane in the country.

He holds a master’s degree in mechanical engineering from the University of Karlsruhe, Germany, and worked at Robert Bosch GmbH for 21 years, the last 12 years as a director of different plants in the Netherlands, Germany and Brazil, working on turnkey projects for the food and pharmaceutical industries.

Benjamin Gall

COO Gruen

Responsible for engineering, operations and implementing Gruen’s strategies.

He holds a degree in electrical engineering and a postgraduate degree in Corporate Management from Kalaidos University in Zurich, Switzerland. He has worked for multinationals such as Franke, Sigpack Systems AG and Bosch Technology Brasil, where he was responsible for designing, manufacturing and installing turn key packaging systems.

Why Gruen Biogás PSA?

LOWER INITIAL INVESTMENT, LOWER OPERATING COST, HIGHER PROFITABILITY:

This represents our contribution to the energy matrix transition process in Brazil.

Experience the exclusive advantage of being partnered with the sole industrial-scale PSA manufacturer for biogas in Brazil, providing you with unrivaled expertise and 100% local technical support.

Unlock the possibilities of financing your equipment through flexible FINAME credit lines or our reliable partner, Vert Capital.

Now is Gruen!

In Europe, biogas purification commenced in the 2000s with the implementation of washing systems and membrane technologies. Both systems showed severe operational issues after some time of operation and new processes based on PSA (Pressure Swing Adsorption) coming from industrial gas purification were developed.

Washing processes are no longer used for new projects and as membranes were found to be less resistant to biogas contaminants and are mainly used for smaller installations only. PSA systems are continuously regenerated and work with the same level of efficiency, simplicity and easiness of operation for 20 years and longer. Moreover, they do not generate toxic waste and consume minimal energy.

Gruen Biogas utilizes its proprietary technology based on industrial PSA processes to purify natural gas and hydrogen. The technology has the capability to efficiently process high volumes of biogas, achieving a high methane recovery rate with excellent adaptability to accommodate variations in flow rates and component concentrations, all while ensuring the biomethane quality according to the specifications outlined by the ANP – National Petroleum, Natural Gas, and Biofuels Agency.

Gruen Biogas production lines can process biogas from digestion of biomass as well as biogas from landfill sites with up to 30% of N2. Furthermore, Gruen Biogas possesses proprietary biogas pre-treatment technology designed to effectively eliminate contaminants commonly found in biogas from various sources, including H2S, NH3, VOCs, and siloxanes.

By issuing carbon credits, producers and investors in the production of biomethane can boost the profitability and economic sustainability of their project.

Gruen Scope

of Supply